Standardization refers to the formulation, publication, and implementation of standards for repetitive things and concepts in social practices such as economy, technology, science, and management, in order to achieve the best order and social benefits. Group standardization is the process of formulating and implementing company standards, as well as implementing relevant national, industry, and local standards, for repetitive things and concepts within the scope of company production and business activities, with the goal of achieving the best production and business order and economic benefits in the industry.

The activity of establishing common and reusable rules for actual or potential problems in order to achieve the best order within a certain range is called standardization. It includes the process of developing, publishing, and implementing standards. The important significance of standardization is to improve the applicability of products, processes, and services, prevent trade barriers, and promote technological cooperation.

Background

Continuous development of the industry

After years of research and experimentation in China, the production and manufacturing technology of biomass particle forming equipment has become increasingly mature, and a relatively complete industrial and technical system for biomass particle forming equipment has been formed.

Lack of unified standards

However, the technology platform and basic research are relatively lagging behind, and empirical design still accounts for a considerable proportion. Product design lacks support from experimental and testing conditions. In recent years, through technology introduction, digestion and absorption, independent development, and joint venture production, the manufacturing technology of biomass particle forming equipment in China has developed rapidly. Although the manufacturing technology of biomass particle forming equipment in China has made significant progress, there is a lack of unified standards for equipment production.

Market mixed with good and bad

The market is mixed with fish and dragon, and the quality is uneven, with a large number of unqualified products flooding the market, resulting in low production, difficulty for investors to choose, and high production costs for after-sales accessories.

There is a saying that goes, first-class enterprises set standards, second-rate enterprises make brands, and third-rate enterprises make products. In this context, Shandong Bolida&Rotexmaster Machinery Co., Ltd., as an industry leader who has been deeply engaged in the industry for over a decade, deeply feels the responsibility is significant. The lack of standardized biomass pellet machines has restricted the development of the industry and prevented it from breaking trade barriers.

Shandong Rotexmaster Machinery Co., Ltd. and Shandong Bolida Machinery Co., Ltd. jointly drafted the "Group Standard for Biomass Particle Forming Machines" (hereinafter referred to as the "Group Standard"), which emerged as the times require. The issuance of this document fills the gap between national and industry standards. Unified equipment manufacturing standards are conducive to reducing carbon emissions in production, reducing production costs, increasing solid fuel production, improving the level of resource utilization of crop waste, and contributing to the "dual carbon" strategy, which is a milestone event in the industry!

Qualifications for participating in group standard development

1. Industry influence

The enterprises participating in the preparation of standards must be leading or representative enterprises in the industry, with a large industry scale and influence.

2. Technology leadership

The participating units have certain technological leading advantages and technological strength in China or the industry in terms of relevant technologies.

3. Industry representativeness

Participating units need to have considerable authority in relevant domestic industries or fields, as well as representative achievements and advantages.

4. Industry applicability

The technical requirements and process indicators included in the drafted relevant standards need to have broad applicability in China or the industry.

Shandong Bolida&Yuguan Machinery Co., Ltd. has been striving for more than a decade to pursue its dreams and move forward with determination. Over the years, it has been measuring the development of the industry, constantly keeping up with the times, gathering momentum, meeting the qualifications for setting standards mentioned above, and reaching new heights, contributing to the development and adoption of group standards as an enterprise.

The Road to the Birth of Group Standards - Development Process

proposal

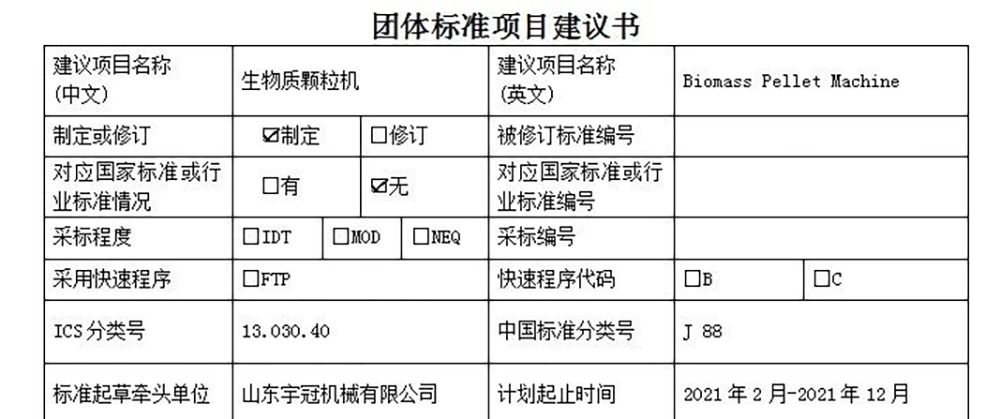

Mainly aimed at the development or modification of group standards for biomass particle forming machines, and submitting suggestions or plans for discussion and decision at the meeting.

Project approval

The group standard approval for biomass particle forming machines is mainly based on the project application submitted by the demanders and developers of the standards, including the significance and purpose of formulating the standards, explanations of domestic and foreign situations, and descriptions of the main technical elements and parameters of the standards.

draft

After the official establishment of the group standard, it is necessary to determine the drafting personnel. The work of the drafting personnel mainly includes: data collection, necessary experimental verification, domestic and foreign situation analysis, and content research and exploration.

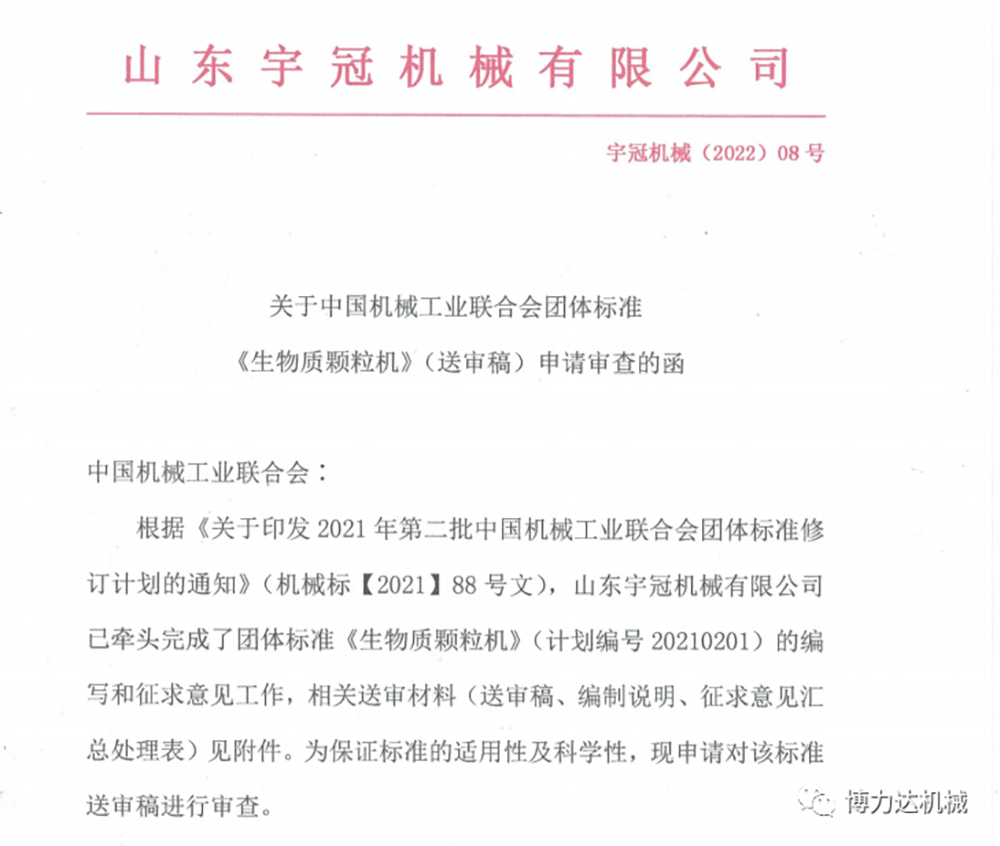

Soliciting opinions and reviewing

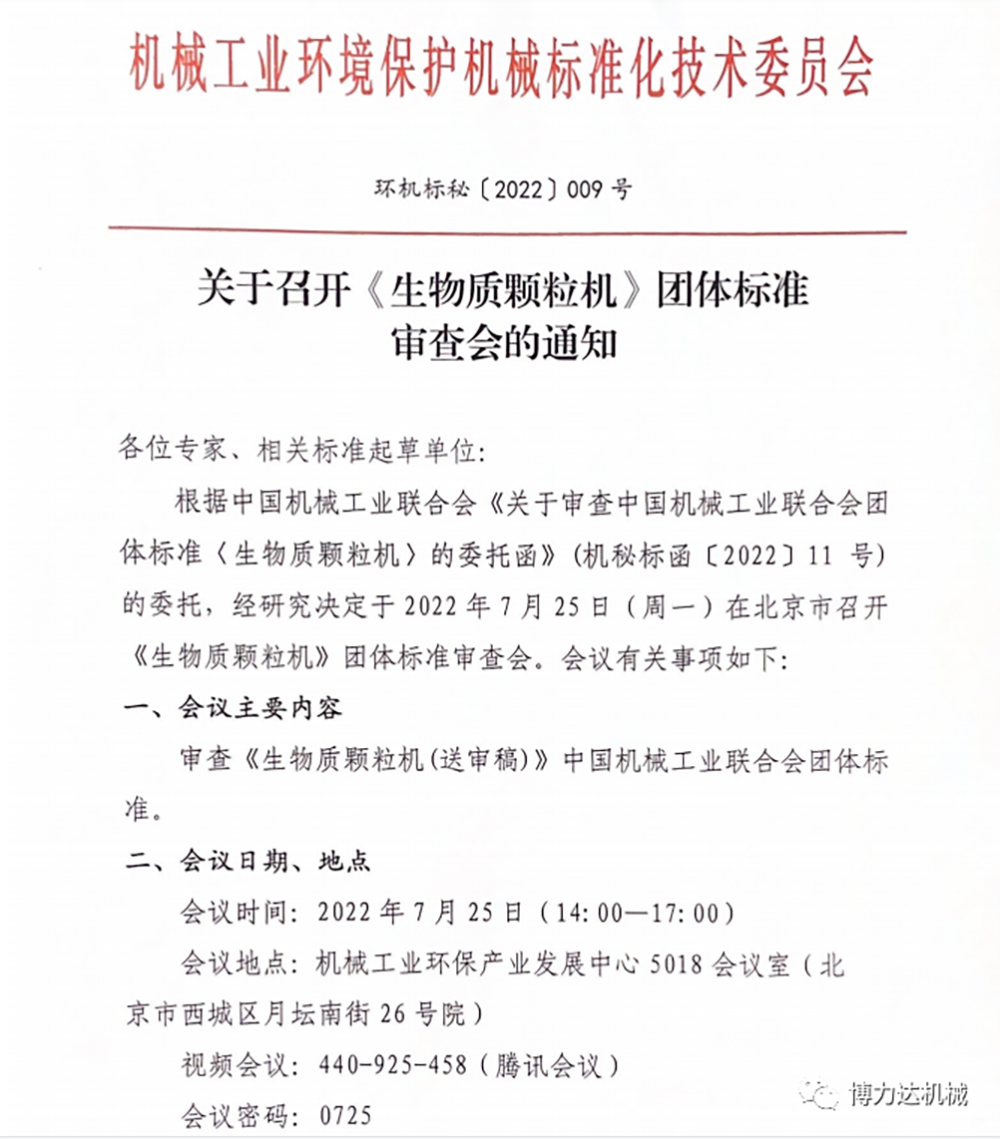

The main forms of soliciting opinions are letter solicitation, online public solicitation, or conference solicitation. Shandong Bolida&Rotexmaster Machinery Co., Ltd. submitted the application review letter to the China Machinery Industry Federation. On July 25, 2022, Shandong Bolida&Rotexmaster Machinery Co., Ltd. invited many scholars and experts in the industry to participate in the review meeting. At the meeting, everyone expressed their own opinions, spoke freely, and jointly promoted the improvement and implementation of group standards. Finally, the Deputy Director of the Working Committee of Group Standards Experts of the China Machinery Industry Federation, the Secretary General of the Technical Committee for Standardization of Machinery Industry Environmental Protection Machinery Vice President of Beijing Guoneng Zhongdian Energy Conservation and Environmental Protection Technology Co., Ltd., Executive Vice President of CITIC Geyi Circular Economy Co., Ltd., Deputy Chief Engineer of China Enfei Engineering Technology Co., Ltd., Professor at Beijing University of Chemical Technology, Researcher at Shandong Agricultural Machinery Science Research Institute, Secretary General of the Civil Clean Stove Special Committee of China Rural Energy Industry Association, Chairman of Beijing Weili Environmental Protection Technology Group Co., Ltd The General Manager and other professionals of the Luanxian Baixin Straw Utilization Farmers' Professional Cooperative jointly discussed and approved the proposal.

At the same time, many scholars in the industry are also continuously paying attention to the development of group standards for biomass pellet machines. Professor Yang Shiguang, a professor at North China Electric Power University, a director of the China Biogas Society, a director of the China Rural Energy Industry Association, a member of the Energy Industry Rural Energy Standardization Technical Committee, and Director Xiao Mingsong, a director of the New Liquid Fuel Special Committee of the China Rural Energy Industry Association Zhao Yongqiang, the supervisor of Hengshui Sanmu Energy Technology Co., Ltd., provided many constructive suggestions for the "Group Standards", fully reflecting the strong professionalism and academic rigor of the proposers, greatly promoting the promulgation and implementation of the "Group Standards".

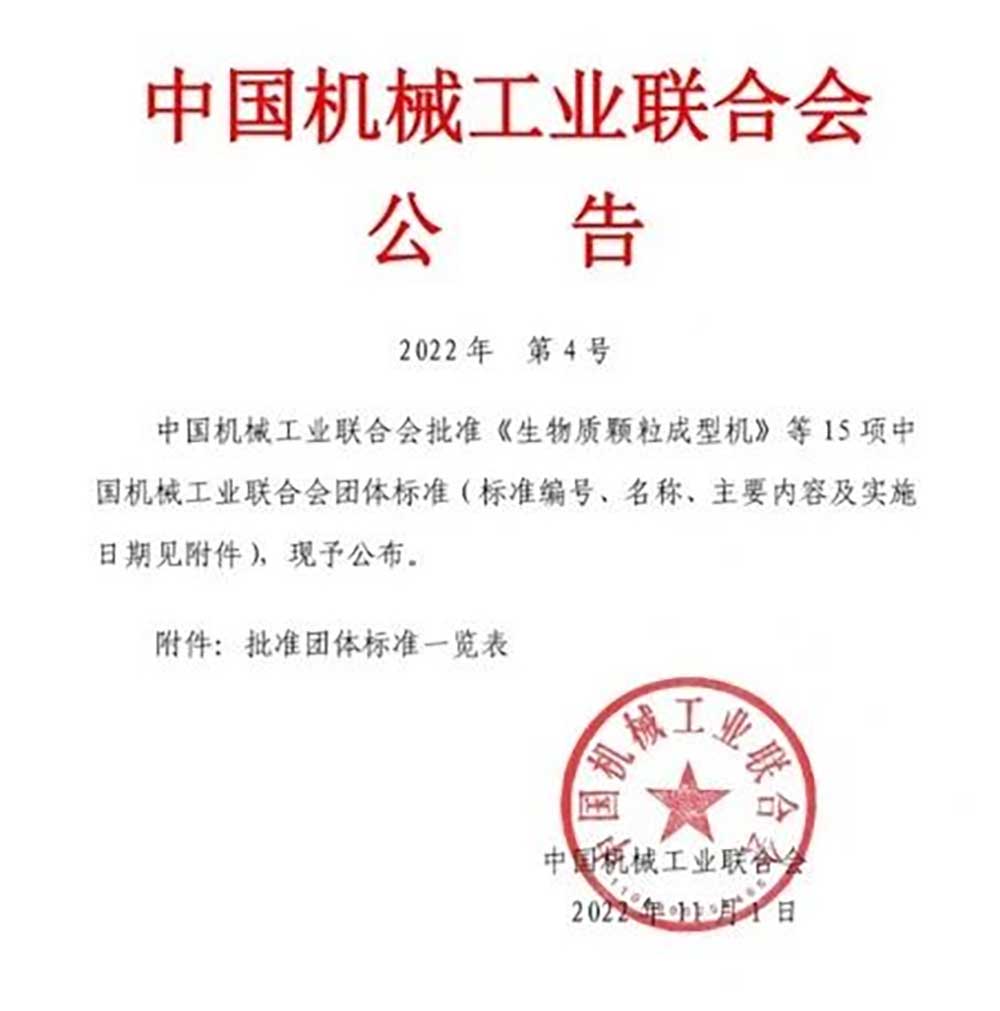

Pass and Publish

After review, the documents will be submitted for approval and inquiry. With the efforts of various sectors in the industry, the "Group Standards" for biomass particle forming machines have been implemented, filling the gap in national and industry standards.

On April 27th, the 15th Warm Expo was held in full swing, with a crowd of visitors surging during the exhibition. The industry's internal meetings and sharing were also in a positive atmosphere, with experts and business operators at the forefront of the industry exchanging and discussing, pushing the conference atmosphere and discussion results to one climax after another.

At noon on that day, Zhang Ming, Executive Vice President of Shandong Bolida Machinery Co., Ltd., attended the meeting and took this opportunity to officially announce the implementation of the group standard for biomass particle forming machines at the meeting!

Christine, Executive Vice President of Shandong Bolida Machinery Co., Ltd., gave a detailed introduction to the investment and construction of biomass pellet fuel plants at the meeting, providing clear ideas and methods for those who want to engage in biomass pellet production from multiple aspects such as plant selection, analysis of their respective raw materials, costs, and plant selection. Finally, Zhang Ming solemnly announced in the conference room that the group standard for biomass particle forming machines had been officially passed and implemented. The applause from the venue was endless, celebrating a historic moment and milestone event in this industry, and promoting the environmental protection, solid waste, and new energy industry to reach new heights!

Shandong Bolida Machinery Co., Ltd., established in March 2017, is located in the West side of Dazhan Community in Mingshui Street, Zhangqiu District, Jinan City, Shandong Province with superior geographical location and convenient transportation.

View MoreCopyright © Shandong Bolida Machinery Co., Ltd., All Rights Reserved | Sitemap | Powered by